How to Remove

a Mustang T5 Transmission

Posted by: Clemens9

Since lots of people are

always asking how to drop a transmission, I took lots of pics

last time I did it so I could make a write-up.

First step- Get the car as high off the ground as possible. Make

sure you get all 4 wheels off, and leave plenty of room in the

front to pull the tranny out of and to sit under comfortably.

Second step- Remove exhaust. Its easiest if you pull the O-2

sensors off first, they sometimes get in the way. Then, make sure

you have a can of PB-blaster to remove the rust off the header

bolts, they can be a pain in the ass and add hours to the time if

you cant get them off. Spray lots on there, and let it sit for

about 5 minutes, and then take the nuts off of the header studs.

After that, remove the other side of the H or Y pipe from your

cat-back system.

Third step- drain the fluid from the transmission. This is

important because if you remove the driveshaft with the fluid

still in the transmission, the fluid will come out the tailshaft

and get everywhere. Use the bottom drain plug in the picture (not

the circled bolt, but the red drain plug to the left of it).

edit- Remove the Shifter handle and bezel. You must go in the

car, unscrew the shifter top, take the bezel off, and then unbolt

the handle from the base of the shifter. When you are done, the

base of the shifter should look like this.

Fourth Step- Remove the driveshaft. For some people, this is the

hardest part. You need to make sure the rear end is high enough

to get a wrench and a breaker bar under there. Put the e-brake

on, and then remove each bolt one at a time. When you finish the

two bolts you can get off, take the e-brake off, rotate the

wheels by hand, and then set tbe brake again and take off the

rest of the bolts. You need a 12-pt 12mm wrench I believe (might

be 13mm). Some people can get it off with a ratchet head, but i

can never fit them in there because of the tight clearenced. You

will need some type of breaker bar also because those bolts are

on REALLY tight. Make sure you mark the driveshaft alignment. Put

a mark where the driveshaft was attached to the rear end so you

can put it back in the same place.

Fifth step- Removing the transmission to bellhousing bolts. This

is relatively easy. You just have to remove the 4 bolts that keep

the tranny attached to the bellhousing. Two of them are the

circled bolts in this picture, and the other two are above them.

You will need some extensions, and maybe a universal joint to get

the top ones off. Once these are off, only the input shaft and

the crossmember are holding the transmission in place. Also

remember to remove the 2 or 3 electrical connections that are

attached to the transmission.

Sixth step- First, place a jack under the transmission, so it

doesn't start to fall. Next, start removing the crossmember bolts.

These are either 2 or 4 bolts that keep the transmission mounted

to the body of the car. Once these are removed, only the input

shaft is keeping it in place.

Seventh Step- Removing the transmission. You can either slowly

lower the jack while pulling it back out of the bellhousing, or,

if you are a bigger guy, lift the tranny up, remove the jack, and

pull it out and onto your chest. It weighs about 80-90 lbs, so

make sure your ready for it when it drops. Once its out, simply

place it on the ground and pull it from under the car.

Eighth Step- Remove the starter. First, unhook the battery, so

you don't electrocute yourself. Next remove the starter by taking

out the two bolts that attach the starter to the bellhousing.

They are located on the other side of this picture, where the

circles are. You will need a deep socket or a wrench to get them

off. You can leave the starter hanging in place, it just has to

be unbolted from the bellhousing.

Ninth Step- Remove the bellhousing. This is straight forward.

This is a bad picture, but I don't have anymore of it. Remove the

clutch cable from the clutch fork first, and then remove the C-clip

that holds the cavle to the bellhousing so you can completely

remove it. Then, just remove the 6 or 8 bolts that hold the

bellhousing to the block. There might be one or two smaller ones

that attach the bellhousing to the thing metal plate, so remove

them also.

Tenth Step- Remove the clutch and pressure plate. This is also

straight forward. Just remove the 6-8 bolts that hold the

pressure plate and clutch disk onto the flywheel. Be ready when

you take it off, there are pins holding it in place, but its

surprisingly heavy when you pull it off. Make sure you mark where

you removed it from on the flywheel for balancing if you are re-using

the same clutch and pressure plate.

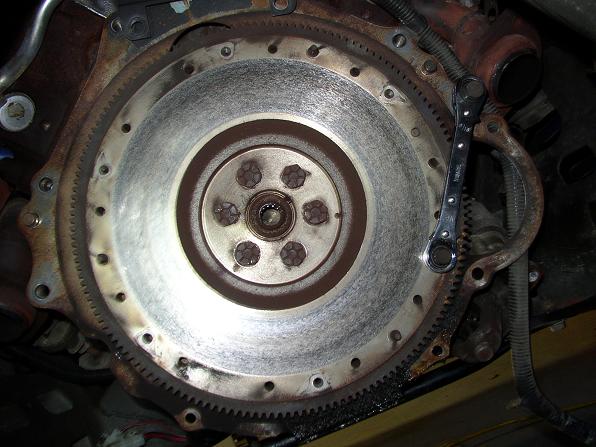

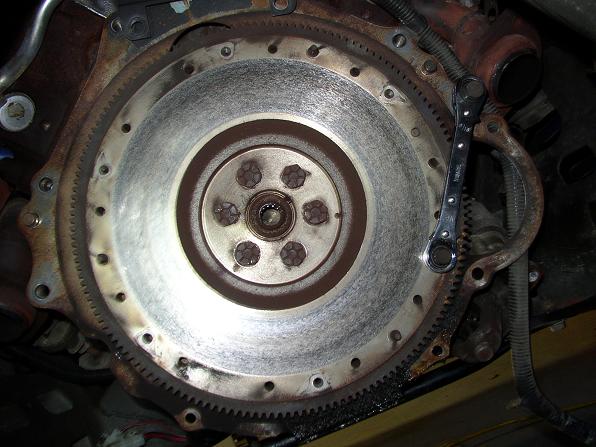

Last step- Remove the flywheel if necessary. If you are putting

in a new clutch, remove the flywheel so you can have it

resurfaced. You will notice something when you try to take them

off, the engine will turn. You will have to have someone hold the

crank bolt so the engine doesn't turn while you remove the bolts.

If you don't have another person available, either attach a C-clamp

to the flywheel teeth to keep it from moving, or set up something

else. This thing is heavy, so watch it when you remove it. The

flywheel will only go back on one way, so you don't have to mark

it.

This is the pic that has

everything put together. The clutch fork is mounted correctly on

the bellhousing, and the TO bearing is on the fork.

This is the clutch fork separated from the bellhousing. There are

two prongs on the fork that hold it onto the ball.

This is the TO bearing mounted correctly on the clutch fork. The

input shaft goes though the hole, and the TO bearing sits on the

pressure plate. It should sit on those prongs if its on

correctly, allowing it to pivot.

This is the back side of the fork, showing the other side of the

TO bearing.

Posted by:

ttbit

If you would like to add this

pic, it is a little trick on removing those flywheel bolts.

Someone suggested it on this forum, and it worked great for me!

Just look for the cheapo wrench. Not

the greatest pic, but you get the idea. You just have to switch

sides when you have to re-torque the bolts!